INTRODUCTION

The burning heart of our fast cars, yeah you are right, I am talking about engine. It’s the power unit we have to spin our car wheels. The entire thrill we have got while driving depends on the capacity of this power unit, and the limits up-to which we can push its components to operate safely. It is the combination of all parts of an engine that makes a car to move faster and faster.

So let’s just dig out what it’s components are, and how precisely they must be engineered to get the maximum power out of an engine.

MAIN PARTS OF AN ENGINE

1. Engine Block

Engine block is an important parts of an engine. It is made by pouring the molten iron or aluminum alloy into a mold. The mold is made such that we should have required number of holes in the casted block, which are said to be the number of cylinders of an engine or engine cylinders. The diameter of these holes is called the bore of an engine.

We have some more holes along the length of engine cylinder, these are water and oil flow paths required for cooling and lubrication of an engine. Oil paths or vents are rather narrower than water flow vents.

What else we have in an engine block is semi-circular seats. On these seats half part of thrust bearings (thrust bearings come in two parts) are mounted, then we place crankshaft in these thrust bearings. But we still need to hold crankshaft to the engine block, to do that we have bearing-caps.

Bearing-caps have a semi-circular seat for other half part of thrust bearing. To mount the bearing-cap with engine block we use studs and nuts. One threaded end of stud goes into internal threaded hole in engine block, and other threaded end of stud goes into hole in bearing-cap and we fasten them together with nut. Two studs are used for holding one bearing-cap in place.

Now that we know that why we have semi-circular seats, in an engine block, let’s take a look what we going to do with cylindrical holes in the block.

2. Piston

Piston is a cylindrical structure with a flat surface called crown at the top. Piston is the component that moves up and down in an engine cylinder. Wait what it would cause?, friction if one cylinder (piston) moving up and down in another cylinder? Yeah to overcome this problem groves are made on the circumference of this cylindrical structure (piston). And we place rings in these groves called piston rings. So now the whole cylindrical structure is not rubbing with engine cylinder and only piston rings are in contact with engine cylinder thus reducing friction to a great extent.

Now how we go to use this up and down motion of piston, for that we need to know about 2 more things that are connecting rod and wrist pin.

Also Read:

3. Connecting Rod

It is an ‘I’ shape structure whose one end is connected to piston and other one to crankshaft. The piston side end of connecting rod has hole in it. And we have also got a hole in piston’s cylindrical structure just beneath the piston rings. So we align this hole with connecting rods hole and put a wrist pin through it. Wrist pin act as a bearing and connecting rod can move like pendulum beneath piston, though piston’s cylindrical structure is gonna limit its motion. To make sure that wrist pin should not move from its position it is restricted by snap ring at both sides.

Other end of the connecting rod can be split into two parts. First is semi-circular journal bearing seat, which is placed over crankshaft after installing the half part of journal bearing, in the seat. Other half is journal bearing cap. These two parts are bolted together, holding crankshaft in between. Thus piston is now connected to crankshaft through connecting rod.

4. Crankshaft

As name suggests it is designed in such a way to convert linear (up and down) motion of piston into rotational motion. It works same as slider- crank mechanism. Material used for making crankshaft is cast iron generally but we also use forged steel in high power engines where load on crankshaft is too high.

Casting a crank-shaft seems to be an easy task, but it’s not. Once crankshaft is casted it is then machined, which is not that easy considering its shape. Then after machining it requires proper balancing to work properly.

You will generally find some random holes in crankshaft; these holes are for balancing the crankshaft while rotating at high speed.

5. Crankshaft Casing or Oil Sump

It is also called as oil sump. It is a casing which is bolted to engine block, which covers engine from bottom thus called crankshaft casing. It retains lubricating oil in it which is pumped to different engine parts. Crankshaft has got small holes which spills oil towards piston, to remove piston heat and lubricate the piston rings, so it also prevents oil from splashing. We have got a bolt at the bottom of this casing from where we remove used lubricating oil during maintenance.

6. Engine Head

Engine head is casted in the same way as engine block. Its mold is made such that the casted piece must have an opening for air to flow into engine cylinder and an exhaust opening from where the burnt gases will go out. This passage of air flowing in and going out of engine cylinder is controlled by inlet and outlet valves. So engine head also has cylindrical holes to insert valve stem. Furthermore to burn the air-fuel mixture we have to fire it up and how we gonna do that? Yeah we need a spark plug which must produce a spark inside engine cylinder, for this we need cylindrical hole in engine block to put spark plug into engine cylinder. We also have semi-circular seats casted in engine head for camshaft bearings.

Before we discuss all the new terminology we have used to explain the engine block let’s just figure out how engine head is attached to the engine block.

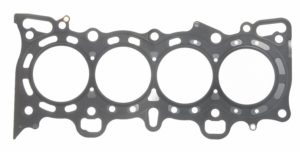

We have 4 internally threaded holes at the top of engine block. Threaded end of the stud gets fastened up in engine block and we have 4 studs fasten up in the same way in the engine block, then we put a gasket whose holes align with the engine block studs. We have 4 holes through the engine head and they align with 4 fastened studs of engine block. So this way we fasten the engine block and engine head with gasket in between together with help of stud and nut assembly.

7. Valves

As we have already know that they control the inlet and exhaust air to go into and out of engine cylinder. Material used to make valves is nickel-chromium iron alloy. It can resist high temperature and have great strength. Valve could be described in two parts- valve stem and valve head. As we already know that we have got cylindrical hole in engine head for valve steam and we also have a valve seat where valve head will rest in engine head. Valve is mounted upside down means valve head is facing engine cylinder. It is so because when there would be high pressure in engine cylinder it would press the valve head against its seat in engine head and thus pressure will be maintained at best.

Also Read:

8. Camshaft

It is a shaft with a number of cam profiles along its length. So it regulates the valves opening and closing time. It does so by pressing the end of valve stem by its cam profile. But we still need a mechanism which would return the valve back to its position once pressed by the cam profile of camshaft. We have valve spring and bucket head tappet assembly for solving this problem.

Now as we have semicircular seats for bearings of camshaft. What retains it to be fixed in engine head while rotating is cam-caps? They hold the other half of journal bearing and have two holes in their casing through which we insert bolts and fasten them in internally threaded holes of engine head thus we hold our camshaft between the casted journal seat in engine block and cam-caps and fasten them up with long bolt.

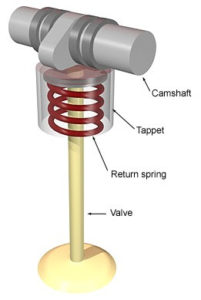

9. Valve Spring and Tappet

Valve spring provides a self-returning mechanism when valve is not being pressed by camshaft. We further have bucket type tappet covering the valve spring. The purpose of tappet is to provide smooth surface for cam to press the valve spring or inlet and outlet valve. The arrangement is like we have valve spring around valve stem and tappet mounted over that spring for smooth surface and camshaft mounted just over it making the valve move up and down using its cam-profile.

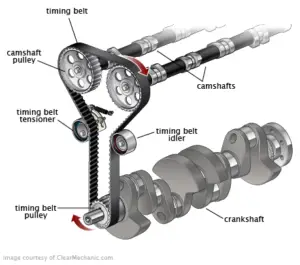

10. Timing Belt

Wonder how camshaft gets its rotational motion to regulate valves. Yeah it’s through timing belt which transmits the motion of gear mounted at crankshaft called crank-gear, to the gear mounted at camshaft. The ration of cam-gear to that of crank-gear is 2:1. So that camshaft would rotate only once in two rotations of crankshaft. Timing belt is made up either from glass-fiber or Kevlar so it does not worn-out easily.

11. Spark Plug

It is the parts of an engine that ignites the air-fuel mixture in the engine cylinder. It produces the spark at right time by using electrical energy of battery. The basic working principle is that when we have high electrical potential at one end and zero or negative potential at other end. And two ends being real very close to each other, it produces an electric field so strong between them that it ionizes the air molecules thus producing spark. And that is in the combustion chamber , It is made up of titanium so that it can withstand a real high temperature generated by high electric potential difference while producing spark.

12. Gasket

A wide variety of materials are used in making gaskets like Teflon, glass-fiber, silicon etc. It is generally a paper like sheet which is placed between engine block and engine head. As we have already discussed that we have both water and oil vents in engine block, so gasket gives insulation from water or oil leaking into engine cylinder or air-fuel mixture from engine cylinder leaking out from joint of engine block and engine head. Aluminum engine blocks are preferred over cast iron because it expends more on heating thus compressing the gasket more, increases the workability of gasket, thus reducing the chances of leakage.

13. Piston Rings

Yeah we have talked about them; they reduce friction between piston and cylinder walls. What else they do?

Piston rings prevent the pressure created by burning of air-fuel mixture from leaking into crankcase. Not only that piston rings scrap down the oil from cylinder walls which is spilled by crankshaft to remove heat from piston. They also transfer heat of the piston to the cylinder walls which are being cooled by water circulation through water vents.